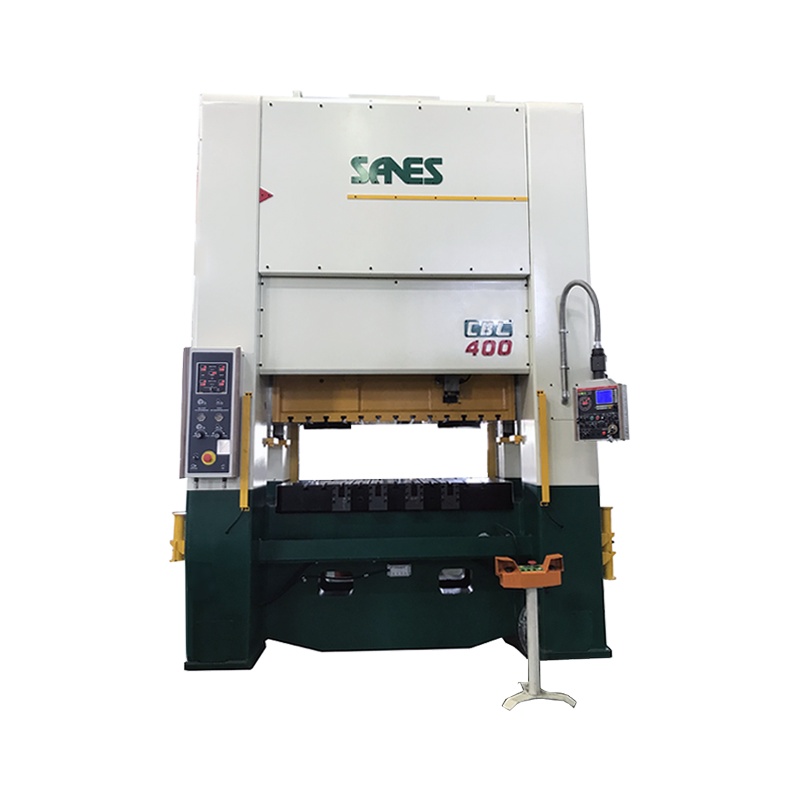

Double Point Link Presses

CBL Series

Unique design for Knuckle Dual Link, holds the slide for about 45 degrees at the bottom dead center. Maximize Material forming time and ensure uniform material flow is achieved.

With FCF(Fine Cold Forming), suitable for the production of intricate parts with coining or sizing. As tradition, these kind of intricate parts only be completed via fine blanking press, but these parts can be completed under FCF(Fine Cold Forming), a very high quality of the stamped parts with a near fine blanking quality is achieved.

Feature

High Rigid Structure, Ensure Parts Precision and Prolong Die Life

Load transmission section uses high rigidity frame can minimized frame deflection, not only in greatly increased high precised production, but also prolonged die service life.

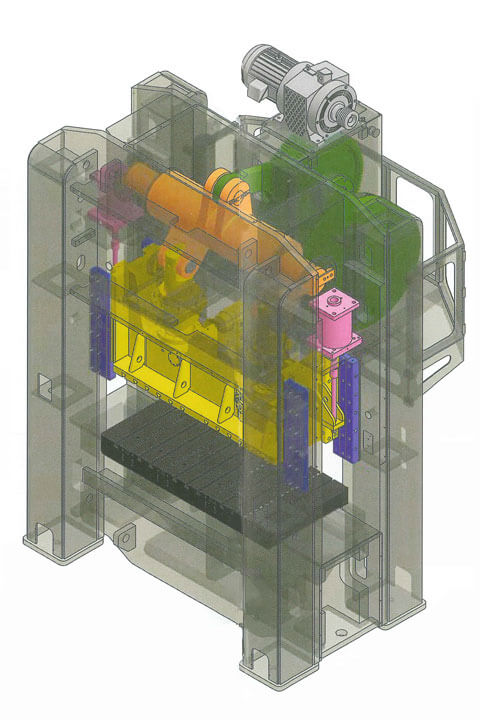

Heavy Duty Knuckle-Link Motion

CBL Series completed with a heavy-duty knuckle-link motion, provide a slow touch speed in the work range ensure a smooth flexible flow resulting in stable, high precision presswork.

Based on high precision manufacturing technology and super quality main gear, the mechanisms of knuckle, the adjust screws, and the joints of slide, overall clearance is 1/3 than conventional presses

High precision torque transmission parts and min. break-through can prolong die life and achieved better precision of completed parts.

High Efficient Separated Dry Type Clutch/Brake completed Safety Operation

High Efficient Separated Dry Type Clutch/Brake completed Safety Operation.

Based on special design Lining, High torgue, Low noise.

Capacity less than 500 tons install Ortlinghaus combination dry type clutch and brake-Made in Germany.

Special Design Long Slide Guides can Keep High Precision Manufacturing in Long Operation Period

Special design 8-sided square long slide guides can complete high endurance during eccentric loading condition. This also can improve die precision and prolong die life.

Use re-circulation lubrication system, can prevent generation of heat from friction.

Easy Installation Based on Floor Mount Design

Completed stored in lower part of the bolster bed knockout system can let press installed on factories floor directly, no need any pit.

This not only can save cost in foundation but also can make factory lay out to be more changeablc.

SPECIFICATIONS

| Model | Unit | CBL-200 | CBL-300 | CBL-400 | CBL-500 |

|---|---|---|---|---|---|

| Capacity | Ton | 200 | 300 | 400 | 500 |

| Tonnage Rating Point (Above B.D.C) | mm | 7 | 7 | 7 | 7 |

| Stroke Length | mm | 120 | 150 | 150 | 200 |

| Stroke Per Minute | S.P.M | 45-100 | 40-80 | 40-80 | 30-65 |

| Die Height | mm | 400 | 450 | 500 | 550 |

| Slide Adjustment | mm | 50 | 50 | 50 | 50 |

| Slide Area | mm | 1650x650 | 2000x700 | 2200x800 | 2200x1000 |

| Bolster Area | mm | 1650x800 | 2000x900 | 2200x1000 | 2200x1200 |

| Main Motor | HPxP | 30HP(INV) | 40HP(INV) | 50HP(INV) | 60HP(INV) |

| Required Pressure | kg/cm2 | 5 | 5 | 5 | 5 |

-Due to continuous research and development, the machine design and specifications are subject to change without prior notice.

-Custom specifications are available upon request.

| Model | Unit | CBL-600 | CBL-800 | CBL-1000 |

|---|---|---|---|---|

| Capacity | Ton | 600 | 800 | 1000 |

| Tonnage Rating Point (Above B.D.C) | mm | 10 | 10 | 10 |

| Stroke Length | mm | 200 | 200 | 200 |

| Stroke Per Minute | S.P.M | 30-65 | 30-60 | 25-55 |

| Die Height | mm | 600 | 650 | 700 |

| Slide Adjustment | mm | 50 | 50 | 50 |

| Slide Area | mm | 2300x1000 | 2400x1000 | 2500x1100 |

| Bolster Area | mm | 2300x1200 | 2400x1200 | 2500x1300 |

| Main Motor | HPxP | 75HP(INV) | 100HP(INV) | 125HP(INV) |

| Required Air Pressure | kg/cm2 | 5 | 5 | 5 |

-Due to continuous research and development, the machine design and specifications are subject to change without prior notice.

-Custom specifications are available upon request.

Related Products

Need Inquire ?

If you need more information or quotation about this product, Our sales representative will reply as soon as possible